AFTER SALES AND MAINTENANCE SERVICE

TGE is in permanent contact with its clients with complete follow-up of the evaporation, crystallization and drying facilities.

For this, TGE has developed quality after-sales service and assists with the maintenance of equipment with professionalism and responsiveness.

TGE is essential support for:

Preventive maintenance

Preventive maintenance

We are able to offer you the following services:

- Detection of vacuum leaks by ultrasonic detection camera

- Annual maintenance on compressors

- Vibratory audits

- Sealing monitoring

- Alignment monitoring

- Carbon seal replacement

- Bearings replacement

- Maintenance on atomizers

- Workshop review

- Turbine balancing monitoring

- Implementation of instrumentation for security

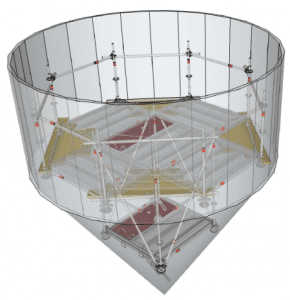

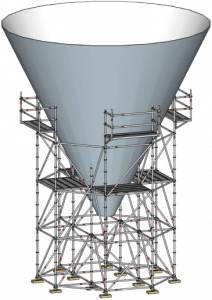

- Dye penetrant inspection of spray-driers (secured by the implementation of scaffolding)

Based on its experience as an integrator, TGE is able to provide the spare parts for evaporators, crystallizers, and spray-driers for all brands

Based on its experience as an integrator, TGE is able to provide the spare parts for evaporators, crystallizers, and spray-driers for all brands

Evaporators

- Gaskets

- Instrumentation

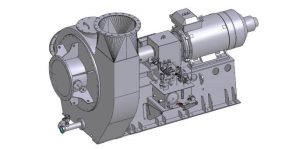

- Centrifugal pumps

- Vacuum pumps

- Plate heat exchangers

- Control valves

- Instrumentation

- Compressors

- Others

Drying towers

- Gaskets

- Hoses

- Pipes

- Accessories

- Instrumentation

- Atomizers

- Others

Technical assistance

Technical assistance

When TGE is called by a client about operation issues of an evaporation or drying facility, it’s because the client has already exhausted all possible solutions internally.

Each time, TGE brings concrete thoughts about the difficulties encountered and allows quick return to normal operating conditions.

Diagnoses

Diagnoses

The strong field experience allows any TGE team to respond to clients’ difficulties, often instantaneous ones.

By phone, on site, through audits, technical diagnosis are performed so as to find optimized conditions of production very quickly.