𝔻𝕆 𝕐𝕆𝕌 𝕂ℕ𝕆𝕎 𝕀𝕋  ?

?

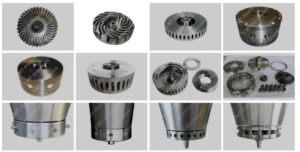

Atomiser turbines produce very homogenous sprays over a wide range of average droplet sizes and have important operational characteristics.

Spray characteristics can be adjusted by changing the speed of rotation and selecting the most appropriate type of turbine according to the characteristics of the product to be atomised and the target specifications in terms of final particle size.

The correct choice of impeller virtually eliminates the possibility of clogging.

The impeller is one of the main components of the atomiser, and it is the most stressed part due to high rotation speed (up to 250 m/sec) meaning high centrifugal forces.

For these reasons, TGE, in partnership with CMT Atomizers, offers turbines manufactured using top-quality materials and according to certain procedures and specifications.

All turbines are carefully statically and dynamically balanced.